Etermar Energia provides a wide range of services for renewable energy projects, with a particular focus on the offshore wind market. Taking advantage of the expertise and experience gained by Etermar over the last 50 years, as well as our unique facilities in Setúbal, we’re able to deliver high-quality, cost-effective solutions.

One single supplier for the client’s needs, throughout different phases of your projects.

Know-how and capability in concrete and steel structures, offering tailormade solutions designed to fit any challenge.

Expertise, large-scale facilities and a skilled workforce enable us to put together solutions for every part of a project’s development cycle.

Plenty of room with a current area of 17 hectares, and clear expansion plans for the offshore wind production area.

Equipped with a fleet of over 30 mobile cranes, yards equipped with overhead cranes, more than 30 operating vessels and 37 support vessels.

Strategic location with a private loading dock in the Port of Setúbal, Portugal, with well-prepared infrastructure that enables us to ship worldwide.

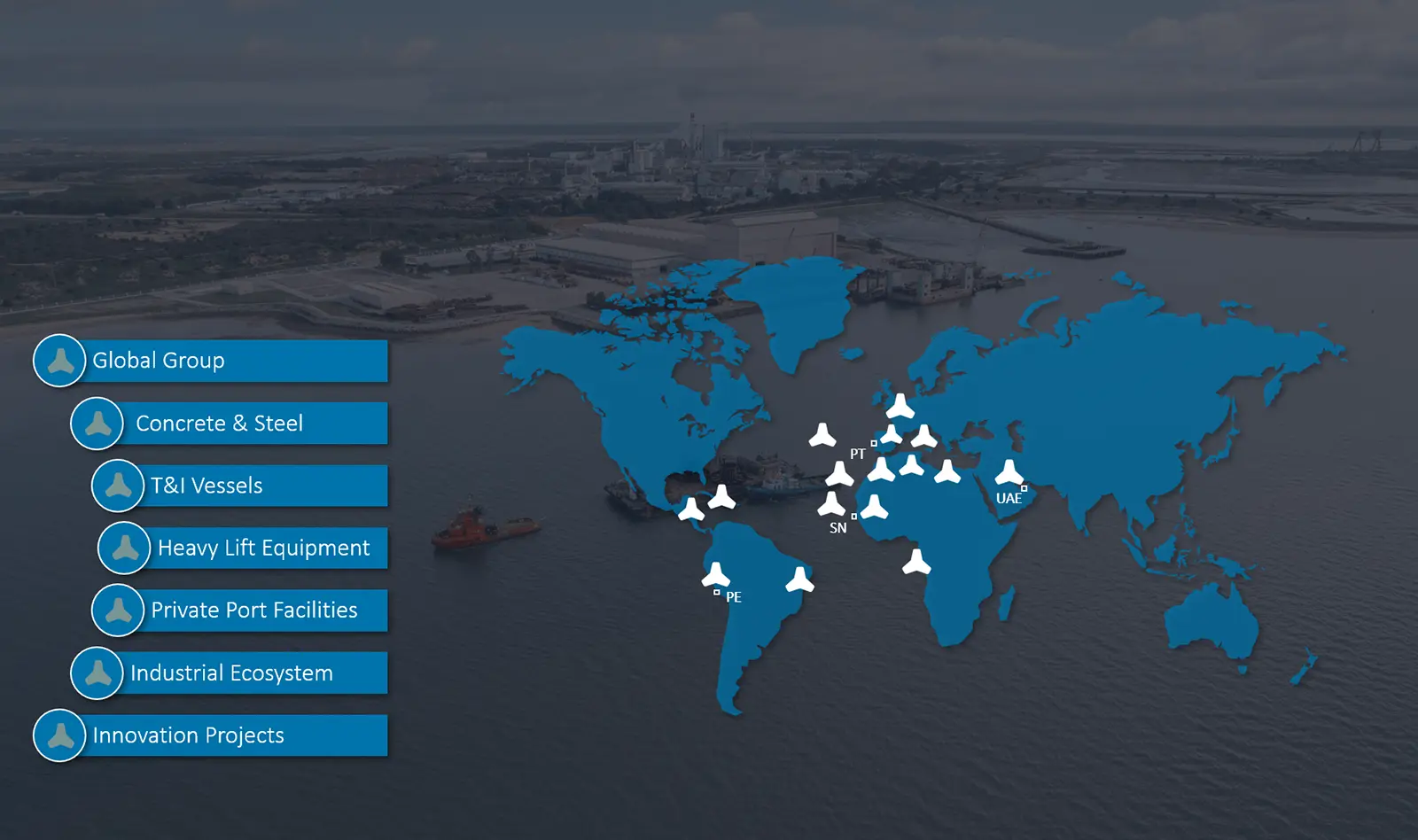

Etermar Group has over five decades of experience and proven track record in four continents. We have worked in innovative projects in 15 different countries from Europe to West Africa, Latin America and Middle East.

With port facilities unbound by concession rules, and backed by the Group’s knowledge and experience, Etermar-Energia is your ideal partner for managing the serial production of concrete and steel structures.

Etermar Energia has experience fabricating fixed structures for use in marine environments, which extends to the fabrication of working platforms, gravity-based foundations, among others. Also, when interfacing fixed with floating structures, Etermar Energia is able to delivery box-anchor solutions and other modular subsea fixed structures, as well as floating foundations.

Etermar Energia’s facilities are also prepared for the fabrication of large steel structures, for sea-going transport, which may include fixed foundation components such as secondary steel access and corrosion protection. Etermar Energia can also build primary steel elements, ranging from supports to landing rings or jacket foundation components. Moreover, based on its own marine experience, Etermar Energia is capable of fabricating and installing seafastening structures for transport scopes.

Linking the group's experience to the new markets, Etermar Energia has capabilities in the fabrication of onshore Energy and Data infrastructures, such as hydrogen plants and datacenter components. Furthermore, Etermar can build the structural elements of tools made of steel, such as heavy lift tools and other similar equipment.

Borrowing on the group's internal Naval Engineering know-how, Etermar Energia is capacitated for shipbuilding, and for repairing vessels and other platforms, as well as their marine components. Accustomed to maintaining and repairing its own fleet, Etermar is at ease with the industry’s specific requirements.